AP Racing Competition Big Brake Kit BMW E46 M3

13.01.10002

BMW E46 M3 front competition brake system featuring AP Racing components. Four piston caliper, 325mm x 32mm Heavy Duty discs.

Two AP Racing, CP8350 calipers, with anodized aluminum mounting brackets and hardware

Two AP Racing CP3908 racing discs with floating anodized aluminum hats

One pair of front Spiegler Stainless Steel Brake Lines

Don't forget to choose your pads!

Don't forget to choose your pads!

Pricing:

$3,099.00

Description

In 2001 BMW released the 3rd generation M3 to much fanfare and it instantly became labeled as one of the greatest sports coupes of all time. With 333bhp, rear wheel drive and a nearly perfectly balanced chassis, the E46 M3 has etched its name in the history books. Now, some 10 years later, these cars have become one of the best bargains for track junkies.

However, at 3400lbs it’s not exactly a lightweight. On track, the M3 is easily capable of mid triple digit speeds and its factory flared fenders allow enthusiasts to cram some substantial rubber in its wells. All this adds up to a ton of inertia and energy when trying to get it whoa’d up. While the M3’s standard cast, pin sliding calipers are perfectly adequate during fast road use and the occasional track day they are not really up to the task of continuous hard lapping, even with the multi-piece Motorsport discs.

So what does the serious track rat do? They upgrade of course. But, not all brake systems are created equal. In fact, most “big brake kits” aren’t really suited towards heavy track use either. While they [usually] increase thermal capacity and may solve fading issues, they generally aren’t optimized for hardcore track use.

However, at 3400lbs it’s not exactly a lightweight. On track, the M3 is easily capable of mid triple digit speeds and its factory flared fenders allow enthusiasts to cram some substantial rubber in its wells. All this adds up to a ton of inertia and energy when trying to get it whoa’d up. While the M3’s standard cast, pin sliding calipers are perfectly adequate during fast road use and the occasional track day they are not really up to the task of continuous hard lapping, even with the multi-piece Motorsport discs.

So what does the serious track rat do? They upgrade of course. But, not all brake systems are created equal. In fact, most “big brake kits” aren’t really suited towards heavy track use either. While they [usually] increase thermal capacity and may solve fading issues, they generally aren’t optimized for hardcore track use.

Caliper Specs

Rotor Specs

AP Racing's Heavy Duty J Hook Racing Discs were specifically designed to handle racetrack abuse. These are the same discs used on the fastest cars at the elite level of motorsports, including ALMS, NASCAR Sprint Cup, etc. They provide increased cooling, less judder, fewer cracks, and an increased service life vs. competing discs. When you run an AP disc, you can be confident that you're using the best parts available at any price point.

Most aftermarket discs have 30 to 48 vanes. Many times those vanes are straight, or non-directional, with a sub-optimal amount of space between disc faces. After extensive CFD and thermal stress analysis, AP designed the Heavy Duty J Hook with 70 vanes and a wide 16.5mm air gap to increase airspeed and heat transfer, while reducing deflection and remaining reasonably lightweight.

The increased directional vane count on the J Hook Heavy Duty Disc amplifies air speed through the disc, reduces air recirculation between vents, and also increases convective heat transfer and heat distribution. In other words, both air and heat move more quickly and evenly through the disc, creating increased stability under the extreme loads of racetrack use. The disc is less prone to coning, distortion, and cracking, while providing cooler running temperatures, less brake fade, reduced judder, and a longer service life.

Most aftermarket discs have 30 to 48 vanes. Many times those vanes are straight, or non-directional, with a sub-optimal amount of space between disc faces. After extensive CFD and thermal stress analysis, AP designed the Heavy Duty J Hook with 70 vanes and a wide 16.5mm air gap to increase airspeed and heat transfer, while reducing deflection and remaining reasonably lightweight.

The increased directional vane count on the J Hook Heavy Duty Disc amplifies air speed through the disc, reduces air recirculation between vents, and also increases convective heat transfer and heat distribution. In other words, both air and heat move more quickly and evenly through the disc, creating increased stability under the extreme loads of racetrack use. The disc is less prone to coning, distortion, and cracking, while providing cooler running temperatures, less brake fade, reduced judder, and a longer service life.

Stainless Steel Lines

Stated simply, some of the automotive brake lines currently on the market are downright frightening. Looking at the fitting and assembly quality makes you wonder where the parts came from, and who put them together. Low grade carbon steel fittings, sloppy stainless weave, no abrasion coatings, substandard linings…the list goes on. When you consider that your brake lines are the critical safety link between your foot and your calipers, these facts aren’t exactly comforting. Not only are some of these parts suspect, it can take forever to actually receive them after placing an order.

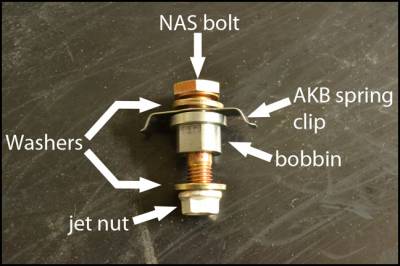

Spiegler does things a little differently. While you may not be familiar with the Spiegler name, they’ve been a trusted producer of stainless steel brake lines in the motorcycle racing industry for some time. Every component in a Spiegler brake line is manufactured to exacting standards in the USA or Western Europe, and these premium components are then hand assembled and tested at Spiegler’s facilities in Dayton, Ohio. You can buy Spiegler Stainless Steel Brake Lines with confidence, knowing that you’ll be receiving the finest product available for your car.

Spiegler does things a little differently. While you may not be familiar with the Spiegler name, they’ve been a trusted producer of stainless steel brake lines in the motorcycle racing industry for some time. Every component in a Spiegler brake line is manufactured to exacting standards in the USA or Western Europe, and these premium components are then hand assembled and tested at Spiegler’s facilities in Dayton, Ohio. You can buy Spiegler Stainless Steel Brake Lines with confidence, knowing that you’ll be receiving the finest product available for your car.

Details

- 13.01.10002

- 13.01.10002

- AP Racing

- New

Categories

Shipping Information

- Item Requires Shipping

- Free FedEx / UPS Ground Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!