Ferodo DS2500 FCP761H Honda Civic Front

FCP761H

Ferodo’s DS2500 racing brake pads represent a new generation of friction material that’s low in compressibility, ensuring a firm pedal while providing great disc and pad life.

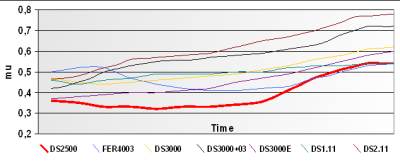

These pads were developed with characteristics that make them perfect for track days, including a consistent coefficient of friction (0.42) at any temperature, providing very predictable braking and great pedal modulation.

These pads were developed with characteristics that make them perfect for track days, including a consistent coefficient of friction (0.42) at any temperature, providing very predictable braking and great pedal modulation.

Pricing:

$224.57

Description

The main characteristics of DS2500 are:

Consistent coefficient of friction (0.42) at all temperatures

Low noise

low dusting

Long pad life

Kind on discs

Race pedal fee

This new generation of friction material is very low in compressibility ensuring a firm pedal, whilst still providing great life for both disc and pad. Combined with low wheel dusting and good noise characteristics this product is the brake pad for the driver who demands the ultimate in track day braking performance.

All part numbers in the range feature a suffix. This suffix identifies the material compound available for each part number. Many part numbers are available in more than one material and are therefore listed accordingly in our catalogues with different suffixes as explained below:

H = DS2500

C = 4003

R = DS3000

M = DS3000 Plus 03

E = DS3000 Endurance

W = DS1.11

X = DS2.11

Consistent coefficient of friction (0.42) at all temperatures

Low noise

low dusting

Long pad life

Kind on discs

Race pedal fee

This new generation of friction material is very low in compressibility ensuring a firm pedal, whilst still providing great life for both disc and pad. Combined with low wheel dusting and good noise characteristics this product is the brake pad for the driver who demands the ultimate in track day braking performance.

All part numbers in the range feature a suffix. This suffix identifies the material compound available for each part number. Many part numbers are available in more than one material and are therefore listed accordingly in our catalogues with different suffixes as explained below:

H = DS2500

C = 4003

R = DS3000

M = DS3000 Plus 03

E = DS3000 Endurance

W = DS1.11

X = DS2.11

Technical Specifications

Manufacturer Part # FCP761H

FMSI # D0465

Composition Semi-metallic

Category Street/Club Sport

Max Operating Temp* 1300 F

Dust Moderate

Noise Low to Moderate

Bite / Mu Moderate

Judder/Vibration Low

Pad wear Moderate to High (on track)

Rotor wear Moderate

FMSI # D0465

Composition Semi-metallic

Category Street/Club Sport

Max Operating Temp* 1300 F

Dust Moderate

Noise Low to Moderate

Bite / Mu Moderate

Judder/Vibration Low

Pad wear Moderate to High (on track)

Rotor wear Moderate

Bedding & Installation

Please follow your vehicle service manual for installation instructions, or have the work performed by a qualified technician.

Ferodo's recommended bedding procedure:

During manufacturing, all Ferodo racing products are subject to “chemical bedding” to stabilise the materials and resins used in construction of the pad. Although this “prebedding” is an effective method and sufficient for low temperature use, the ultimate results are achieved by actual bedding on either the car or dyno...

How ? ...

This subjects the pad to the correct heat and torque loads seen in race conditions. These methods transfer pad material into the face of the rotor leaving a “transfer film” the friction generated between the pad face and this transfer film determines the performance of the “bite”. Correct bedding also ensures that materials which may become compressible are stabilized with the heat and pressure to avoid a “spongy pedal”.

Why? ...

When bedding in the car always try to bed on used rotors. If bedding on new rotors follow the rotor bedding instructions of the manufacturer, as it is important to heat cycle them first before bedding the pads. After fitting the new pads prepare the car by blocking off 50 percent of the brake cooling / air ducts to speed the “heat up time”. When leaving the pit lane apply brake gently at low speed to ensure pads are fitted correctly, build up temperature progressively to approx 350° C (670° F). This enables the heat to distribute around all areas of the pad.

When brakes are at suitable temperature begin bedding process, achieve approximately 70 percent of race speed then perform 25-30 brake applications at half normal race pedal pressure holding on for 4 seconds. When this is completed use a slowing down lap to allow brakes to cool. Return to the pit lane and allow pads to cool completely, check rotor appearance. Transfer film should be constant around rotor face, any “patchy” deposit will result in brake pedal judder. The use of temperature paint on rotors enables more accurate bedding procedures.

Ferodo's recommended bedding procedure:

During manufacturing, all Ferodo racing products are subject to “chemical bedding” to stabilise the materials and resins used in construction of the pad. Although this “prebedding” is an effective method and sufficient for low temperature use, the ultimate results are achieved by actual bedding on either the car or dyno...

How ? ...

This subjects the pad to the correct heat and torque loads seen in race conditions. These methods transfer pad material into the face of the rotor leaving a “transfer film” the friction generated between the pad face and this transfer film determines the performance of the “bite”. Correct bedding also ensures that materials which may become compressible are stabilized with the heat and pressure to avoid a “spongy pedal”.

Why? ...

When bedding in the car always try to bed on used rotors. If bedding on new rotors follow the rotor bedding instructions of the manufacturer, as it is important to heat cycle them first before bedding the pads. After fitting the new pads prepare the car by blocking off 50 percent of the brake cooling / air ducts to speed the “heat up time”. When leaving the pit lane apply brake gently at low speed to ensure pads are fitted correctly, build up temperature progressively to approx 350° C (670° F). This enables the heat to distribute around all areas of the pad.

When brakes are at suitable temperature begin bedding process, achieve approximately 70 percent of race speed then perform 25-30 brake applications at half normal race pedal pressure holding on for 4 seconds. When this is completed use a slowing down lap to allow brakes to cool. Return to the pit lane and allow pads to cool completely, check rotor appearance. Transfer film should be constant around rotor face, any “patchy” deposit will result in brake pedal judder. The use of temperature paint on rotors enables more accurate bedding procedures.

Details

- FCP761H

- FCP761H

- Ferodo

- New

Categories

Shipping Information

- Item Requires Shipping

- 6.5 lbs.

- W4.0000” x H3.0000” x L6.5000”

- Free FedEx / UPS Ground Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!