Hard Dog Honda S2000 Roll Bar

-Flat rate shipping costs from manufacturer-

S2

The Hard Dog S2000 bar is designed for the SCCA competitor that wants to maintain a dual purpose car for street and racing use.

The S2000 bar is compatible with plastic or glass rear window convertible tops and factory roll hoops. If factory roll hoops are removed, brackets are available to attach the stock shoulder harness guides.

Available in many configurations with removable and/or welded diagonal and/or harness bar. If the factory roll hoops and console are removed the harness bar can be installed at the height of the driver's choice.

The S2000 bar is compatible with plastic or glass rear window convertible tops and factory roll hoops. If factory roll hoops are removed, brackets are available to attach the stock shoulder harness guides.

Available in many configurations with removable and/or welded diagonal and/or harness bar. If the factory roll hoops and console are removed the harness bar can be installed at the height of the driver's choice.

Pricing:

$850.00

Description

Features:

- Full interior width

- Complete use of plastic or glass rear window soft tops

- Compatible with factory roll hoops

- Welded or removable main hoop diagonal brace and/or harness bar available

- Durable black powdercoat finish

- Constructed of highest quality 1.75" diam x .120" wall 1026 alloy drawn over mandrel tubing

- Laser cut 3/16" mounting and back-up plates

- Complete hardware kit w/ grade 8 bolts

Installation Instructions

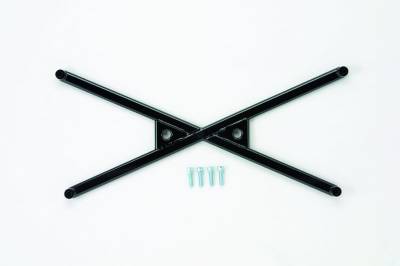

HARDWARE KIT:

2 – front foot plates (1 left / 1 right)

2 – rear foot plates

12 - 3/8" X 1-1/4" bolts

6 - 3/8" self locking nuts

18 – 3/8" SAE flat washers

TOOLS NEEDED: wrenches 2 - 9/16" 10mm 12mm 14mm #2 phillips head screwdriver Floor jack and jack stands hack saw or aviation snips for cutting sheet metal and plastic interior panels belt sander or half round file for fitting plastic interior panels

Installation Steps

TOOLS NEEDED: wrenches 2 - 9/16" 10mm 12mm 14mm #2 phillips head screwdriver Floor jack and jack stands hack saw or aviation snips for cutting sheet metal and plastic interior panels belt sander or half round file for fitting plastic interior panels

Installation Steps

- 1. Remove the seats. Slide the seat belt out of the loop. Unclip the seat belt warning sensor.

- 2. Remove the laundry hooks on the rear trim panel. Pop out the rear trim panel.

- 3. Remove the door sill trim. Pull up carefully.

- 4. Remove the nut under the shifter knob (left hand thread?) and remove the shifter knob.

- 5. Pop the center console up after pulling up the e-brake handle. Disconnect the hazard light and top control switches and pull the console up and over the shifter. Reconnect the top control switch and set the center console aside in driver’s foot well.

- 6. Remove all the screws in the center console, seat area rear trim, rear storage bin, and inside the center storage bin.

- 7. Disconnect the rear trunk switch in the center storage bin.

- 8. Remove the plastic buttons holding the rear package shelf in place.

- 9. Remove all the trim pieces in the trunk. Remove the spare tire.

- 10. Remove the interior trim piece that’s at the very back below the rear window and above the package shelf.

- 11. Remove the final plastic buttons and clips holding the rear package shelf in place. Remove the rear package shelf.

- 12. From the trunk, remove the two screws at the top of the center storage bin and pop off the plastic panel.

- 13. From the trunk, remove the three screws that hold the center storage bin in place.

- 14. From the trunk, remove the two bolts at the bottom of the center storage bin.

- 15. Open the top of the top storage bin and remove the four screws holding the center cover to the storage bin.

- 16. Remove the center storage bin and cover by popping loose the two pop fasteners at the front bottom of the center storage bin and carefully working the unit free. Disconnect the lighter wiring.

- 17. Remove the side interior trim panels.

- 18. Unbolt the bottom seat belt bolts.

- 19. Unbolt the seat belt shoulder loop from the factory roll hoops. The top will need to be adjusted to allow access with a ratchet wrench.

- 20. Unbolt the factory roll hoops.

- 21. Remove the screws holding the factory roll hoop plastic trim to the body.

- 22. Remove the factory roll hoops. Feed the seat belt shoulder mount through the opening in the factory roll hoop plastic trim.

- 23. Remove the sheet metal top motor covers on each side of the seat area. Careful with the carpet pop fasteners. A bolt is behind the carpet.

- 24. Remove the rear top drain trim panels. One pop fastener in the trunk, another on top of the panel, and one in front.

- 25. Unbolt but do not remove the seat belt retractors. Set aside out of the way.

- 26. Remove the storage bin on top of the rear bulkhead.

- 27. Pop the wiring looms loose from the rear bulkhead.

- 28. Unbolt but do not remove the rear bulkhead. Bolts in front, on the sides, and in the trunk. One bolt is hidden under the jute.

- 29. Raise the rear of the car on jack stands.

- 30. Block the front of the car to keep it from rolling.

- 31. Remove the rear wheels.

- 32. Pop loose and clear the wiring from the areas where the roll bar mounts will be set. Unclip the rear ABS sensor lines.

- 33. Put the top partway up and carefully place the roll bar in the car.

- 34. Carefully route the wire looms around the roll bar.

- 35. Line up the roll bar front mounting slot with the stock mounting hole at the top front. Insert one of the 10mm bolts from the top motor covers.

- 36. Align the roll bar with the top mechanism centering the roll bar main hoop between the top arms on each side. Run the top up and down a few times to be sure the roll bar is centered.

- 37. Drill all the holes for the front mounts from above. Use a 3/8" drill bit. Drop the supplied 3/8" bolts into the holes as you go.

- 38. Drill the two inside holes for the rear feet using the same sized drill bit. Drop the supplied 3/8" bolts into the holes as you go.

- 39. From the rear wheel wells, cut the opening required for the front mount backing plates. The opening should start at the top forward end of the wheel well, ¾" from the vertical rib, and extend inward to the front corner where the front panel forms a corner and transitions to the inside part of the well. The opening should be 1" tall. Be careful not to damage the roof of the box exposed in the opening. This is the floor of the rear of the car.

- 40. Cut a slot in the top half of vertical sheet metal support exposed in the opening. Use the punched hole in the vertical metal support as a depth and height reference for the cut.

- 41. Slide the backing plate into the opening. It should clear the rib at the top of the wheel well. The backing plate is positioned correctly if the front of the backing plate hits the front of the wall in the box exposed by the opening. On some S2Ks there’s an accumulation of undercoating in the front of the wheel well that must be removed to get the backing plate positioned correctly.

- 42. Lightly fasten all the front mounts and the backing plate. Lightly fasten the rear mounts and the backing plate using the two inner bolts already drilled.

- 43. From underneath the car and using the backing plate as a template, drill the remaining holes for the rear mounts using the same drill bit as above.

- 44. Install the last two bolts for the rear mounting plates.

- 45. Remove the front bolts one at a time and apply a small drop of blue Loctite to the threads. Reinsert the bolt. Once all the front roll bar mounting bolts have thread locker applied, torque to spec all the roll bar mounting bolts.

- 46. Spray undercoating/sealer into the box exposed by the opening in the wheel wells. Make sure all surfaces are covered and sealed.

- 47. Using sound matting, Dynamat or spray expanding foam insulation from the hardware store to seal the opening. Spray undercoating/sealer over the backup plate and sealer.

- 48. Bolt the wheels back on.

- 49. Lower the car to the ground.

- 50. Carefully trim the rear top water drainage trim panels to clear the roll bar rear braces. The inside front of these panels can interfere with rear package shelf installation if the drainage trim panels are not sitting completely down in their original position. Make sure there’s enough clearance around the roll bar rear brace.

- 51. Carefully trim the plastic pieces surrounding the factory roll hoops. The top edge of the cut should be 2.5" above the bottom part of the headrest opening. Repeatedly test fit the part in the car.

- 52. Carefully route and reattach all the wiring looms around the roll bar.

- 53. Install the rear bulkhead. It will take a little fiddling and you will need to adjust the top position.

- 54. Enlarge the factory roll hoop mounting holes in the rear bulkhead to 5/8".

- 55. Carefully route and re-attach all the wiring looms around the rear bulkhead. The wiring loom with the pale white end clip is for the trunk release in the center storage bin and it routes over the rear bulkhead. The wiring loom with the small gloss black connector is for the power outlet at the front of the center stack. It routes on the floor under the rear bulkhead.

- 56. Install the rear top water drainage trim panels.

- 57. Install the seat belt retractors onto the rear bulkhead tightening the bolts to 25 ft. lbs. Route the seatbelt in front of the rear bulkhead and re-attach the wiring loom to the bulkhead.

- 58. Place the factory roll hoops in position feeding the seat belt shoulder mounts through the holes in the factory roll hoop trim. Check the positioning and make sure all the wiring looms are clear and positioned correctly.

- 59. Install the factory roll hoops. It will take some fiddling and forcing to get the factory roll hoops to line up with the existing bolt holes. In many cases you’ll need to use a big pin punch in the bolts holes to force everything together and get the bolts to start.

- 60. Bolt the seat belt shoulder mount to the factory roll hoop. You may have to remove some of the washers/spacers on the seat belt shoulder mount bolt to get enough clearance to attach it to the roll hoop. You might also need to slightly trim the seat belt mount loop to get things to fit. Additionally you might also have to trim the flange on the seat belt mounting bolt.

- 61. Install the factory roll hoop plastic trim to the body.

- 62. Install the center storage bin onto the rear bulkhead. It has four locator pins that line up with the factory roll hoop plastic trim.

- 63. Trim the side interior trim panels to clear the roll bar main hoop.

- 64. Install the side interior trim panels. They slide over the door flange and clip into the factory plastic roll hoop sides.

- 65. Install the center storage bin and cover. Connect the lighter wiring.

- 66. From the top of the top storage bin, install the four screws holding the center cover to the storage bin.

- 67. Install the two bolts at the bottom of the center storage bin.

- 68. Install the three screws that hold the center storage bin in place.

- 69. From the trunk, install the plastic panel and the two screws at the top of the center storage bin.

- 70. Install the rear package shelf. Connect the four front pop fasteners first starting from one side and working to the other. If the rear water drainage panels are not properly in place you won’t be able to get the parcel shelf to fit. Install the rear plastic buttons last. Check from inside the trunk to be sure they are aligned correctly before popping them in. 71. Install the interior trim piece that’s at the very back below the rear window and above the package shelf.

- 72. Install all the trim pieces in the trunk. Install the spare tire.

- 73. Install the rear trunk switch in the center storage bin.

- 74. Install all the screws in the center console, seat area rear trim, rear storage bin, and inside the center storage bin.

- 75. Install the center console after pulling up the e-brake handle. Connect the hazard light and top control switches and pull the console up and over the shifter.

- 76. Install the shifter knob and tighten the nut under the shifter knob (left hand thread?).

- 77. Install the lower seat belt mounts.

- 78. Install the door sill trim

- 79. Install the rear trim panel and the laundry hooks.

- 80. Install the seats. Slide the seat belt into of the loop. Connect the seat belt warning sensor.

Details

- S2

- S2

- Hard Dog

- New

Categories

Customer Reviews

Total Reviews (1)

Total Reviews (1)

You must login to post a review.

Reviewed by: scott04/14/2016 12:41PM

Product ownership: Less than 3 months

Purchased from: Speed Freaks USA

Comments:

Fit and finish was 100%! install was far easier than I had thought, with all the write ups on line walking me through it was pretty strait forward. The whole cutting the inner fender thing was nowhere near as bad as I was anticipating. All in all I installed by myself in a few hours(not counting the couple hours I spent to disassemble the interior). As always Speed Freaks came through with high quality product to keep me having fun, competitive and safe on track.